Evolution of printing press

Offset printing is a common printing technique in which the inked image is transferred (or “offset”) from a plate to a rubber blanket and then to the printing surface. When used in combination with the lithographic process, which is based on the repulsion of oil and water, the offset technique employs a flat (planographic) image carrier. Ink rollers transfer ink to the image areas of the image carrier, while a water roller applies a water-based film to the non-image areas.

The modern “web” process feeds a large reel of paper through a large press machine in several parts, typically for several meters, which then prints continuously as the paper is fed through.

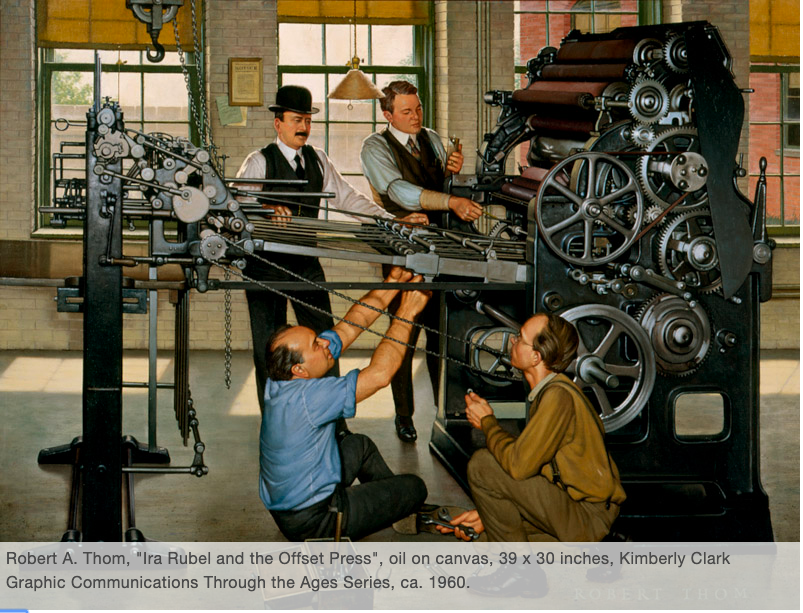

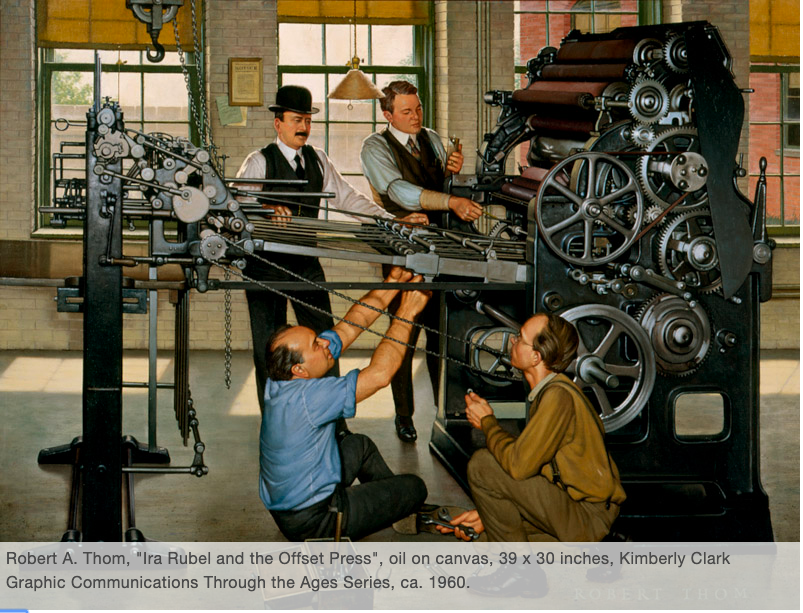

Development of the offset press came in two versions: in 1875 by Robert Barclay of England for printing on tin and in 1904 by Ira Washington Rubel of the United States for printing on paper.

Lithography was initially created to be an inexpensive method of reproducing artwork. This printing process was limited to use on flat, porous surfaces because the printing plates were produced from limestone. In fact, the word “lithograph” historically means “an image from stone” or “printed from stone”

The first rotary offset lithographic printing press was created in England and patented in 1875 by Robert Barclay. This development combined mid-19th century transfer printing technologies and Richard March Hoe’s 1843 rotary printing press—a press that used a metal cylinder instead of a flat stone. The offset cylinder was covered with specially treated cardboard that transferred the printed image from the stone to the surface of the metal. Later, the cardboard covering of the offset cylinder was changed to rubber, which is still the most commonly used material.

One of the important functions in the printing process is prepress production. This stage makes sure that all files are correctly processed in preparation for printing. This includes converting to the proper CMYK color model, finalizing the files, and creating plates for each color of the job to be run on the press.

Offset lithography is one of the most common ways of creating printed materials. A few of its common applications include: newspapers, magazines, brochures, stationery, and books. Compared to other printing methods, offset printing is best suited for economically producing large volumes of high quality prints in a manner that requires little maintenances. Many modern offset presses use computer-to-plate systems as opposed to the older computer-to-film work flows, which further increases their quality.

There are two types of offset printing: wet offset and waterless offset. Wet offset lithography uses a mix of wetting fluids (dampening solutions) to manage ink adhesion and to protect non-image areas. Waterless offset lithography employs a different method where a plate’s non-image areas are protected via a layer of ink-repellent silicon. Waterless offset lithography is relatively new.

Advantages of offset printing compared to other printing methods include:

Disadvantages of offset printing compared to other printing methods include:

Every printing technology has its own identifying marks, and offset printing is no exception. In text reproduction, the type edges are sharp and have clear outlines. The paper surrounding the ink dots is usually unprinted. The halftone dots can be hexagonal though there are different screening methods.

Suspendisse aliquam finibus fringilla. Sed interd imperdiet. Morbi nec velit ut nunc posuere dapibus vel ut odio.